Traveler

MES Delivers:

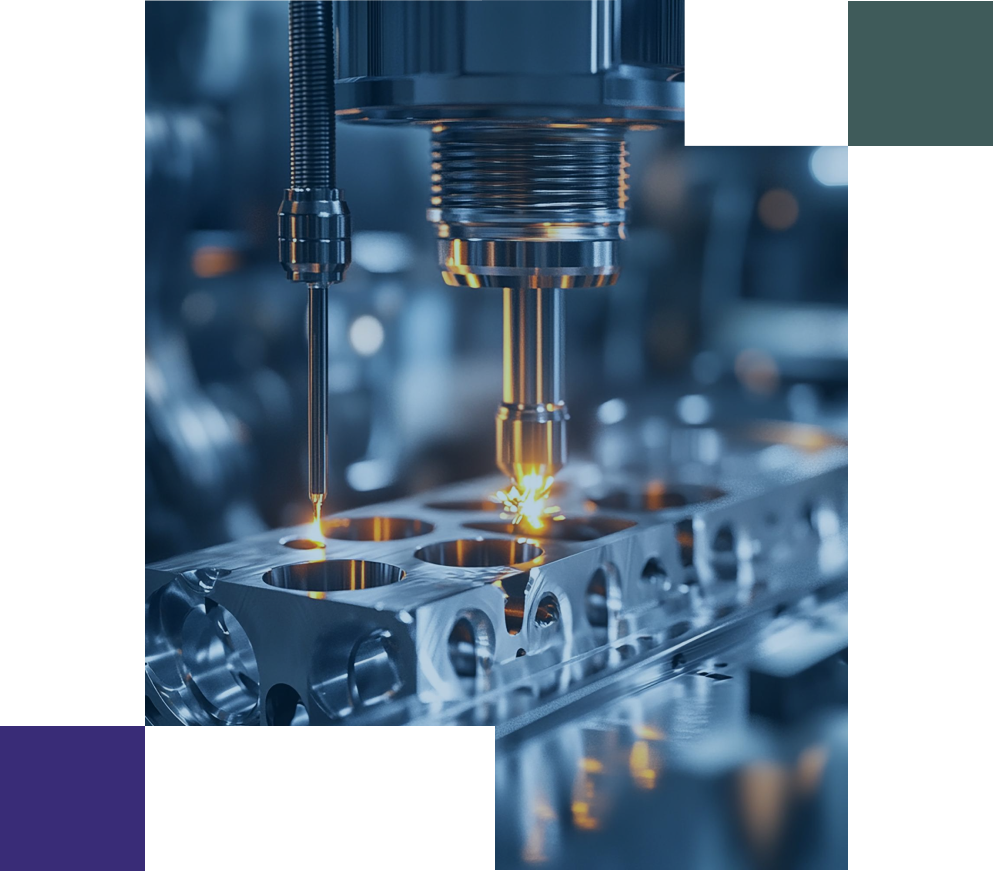

Traveler MES transforms manufacturing by tackling complexities head-on, giving you the tools to do more with less hassle

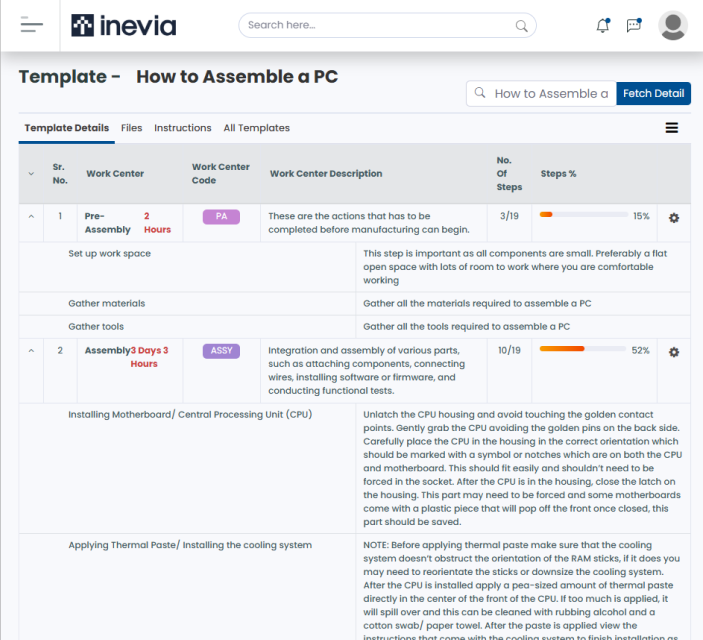

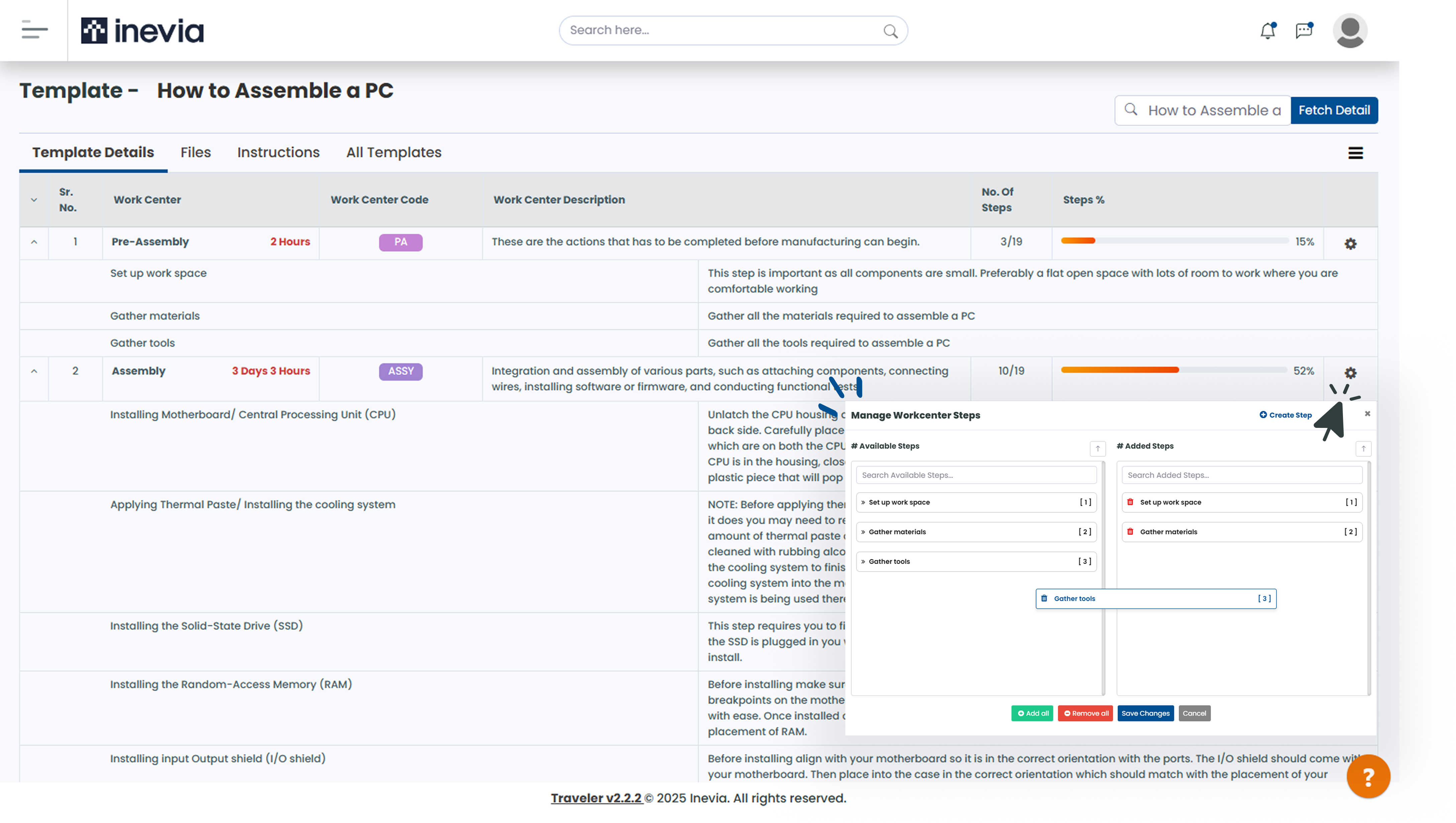

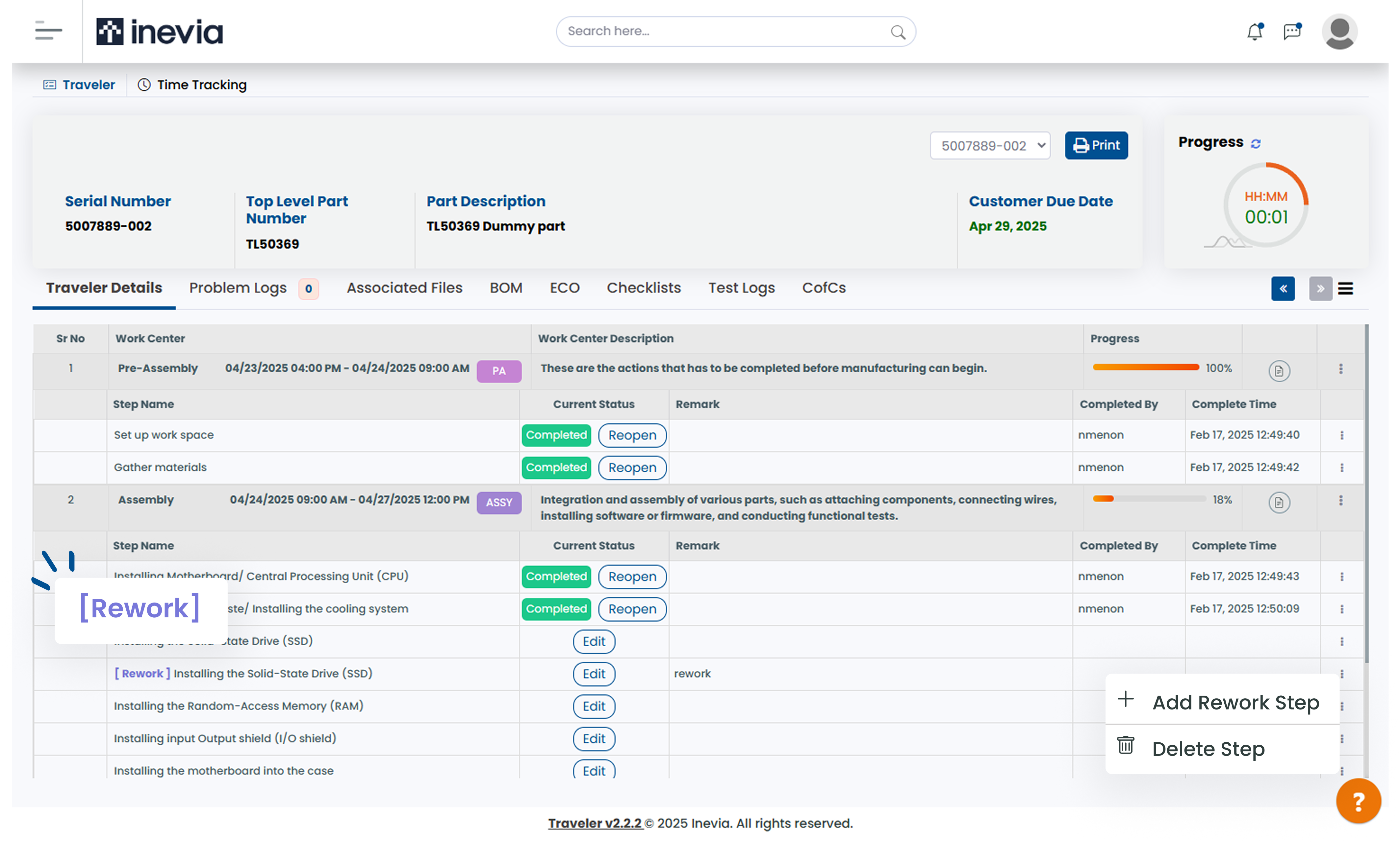

Workflow Management

Define processes that fit your unique needs and set realistic due dates with clear work center timelines.

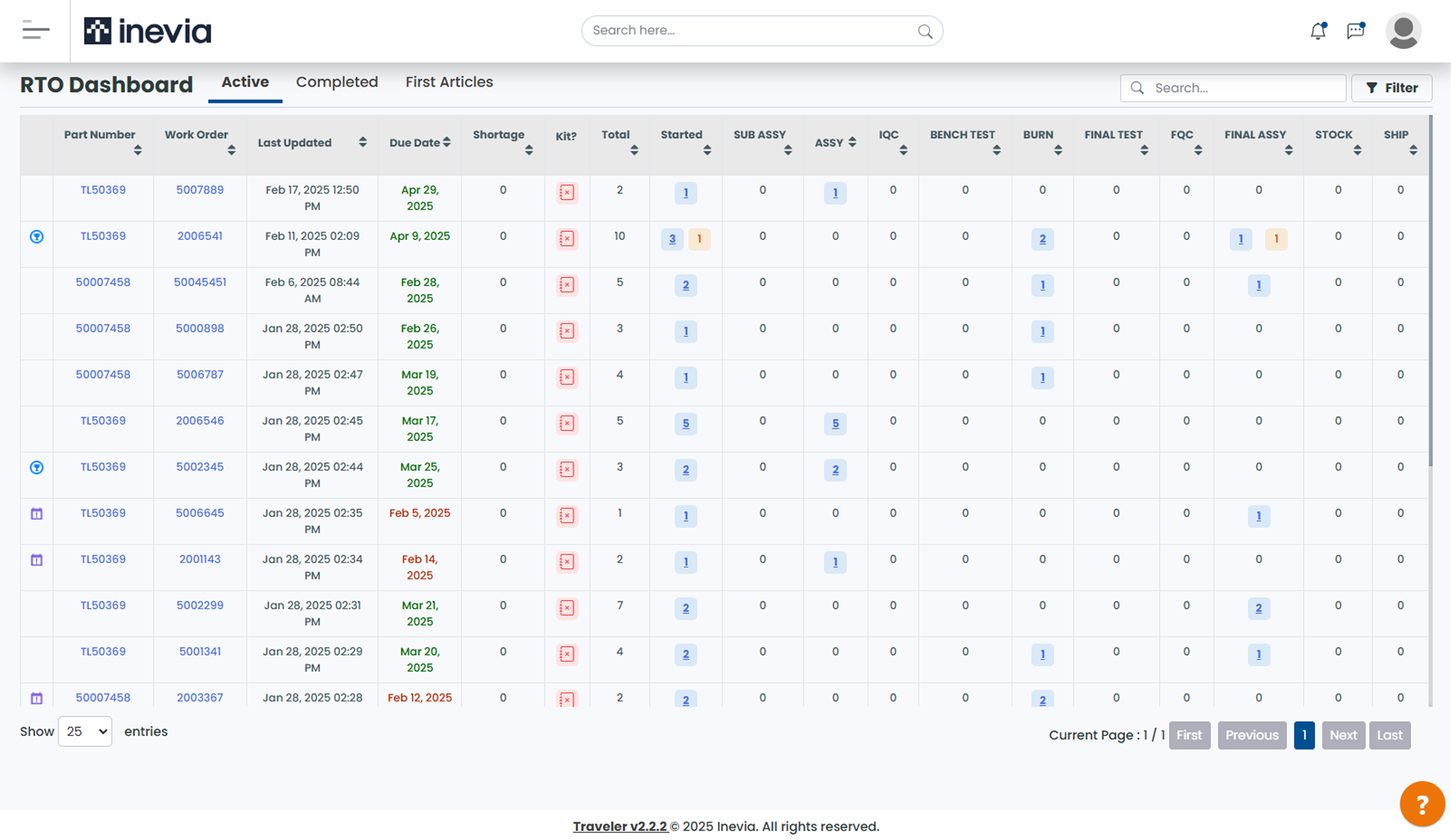

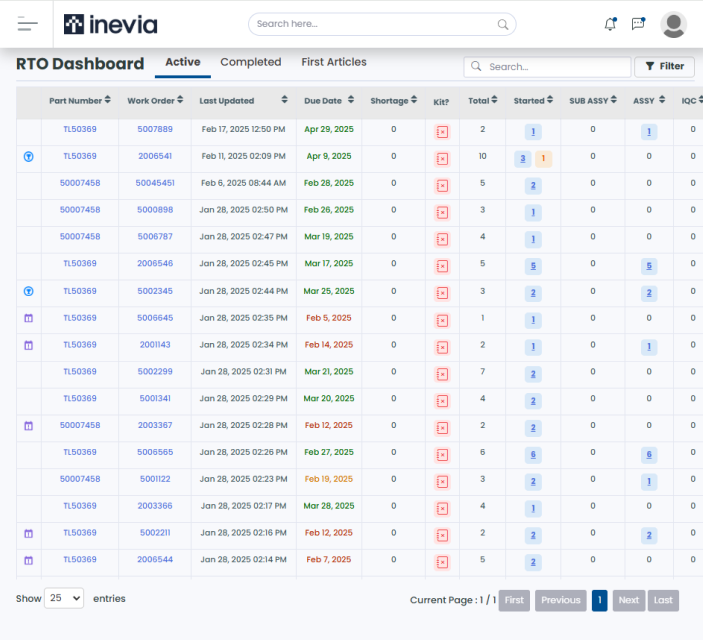

Know MoreProduction Tracking

Empower your team with step-by-step instructions, seamless kitting, and precise labor tracking that eliminates inefficiencies.

Know MoreReal-Time Operations Data

Access live dashboards for work order updates and inventory insights, ensuring you’re always a step ahead.

Know MoreQuality Management

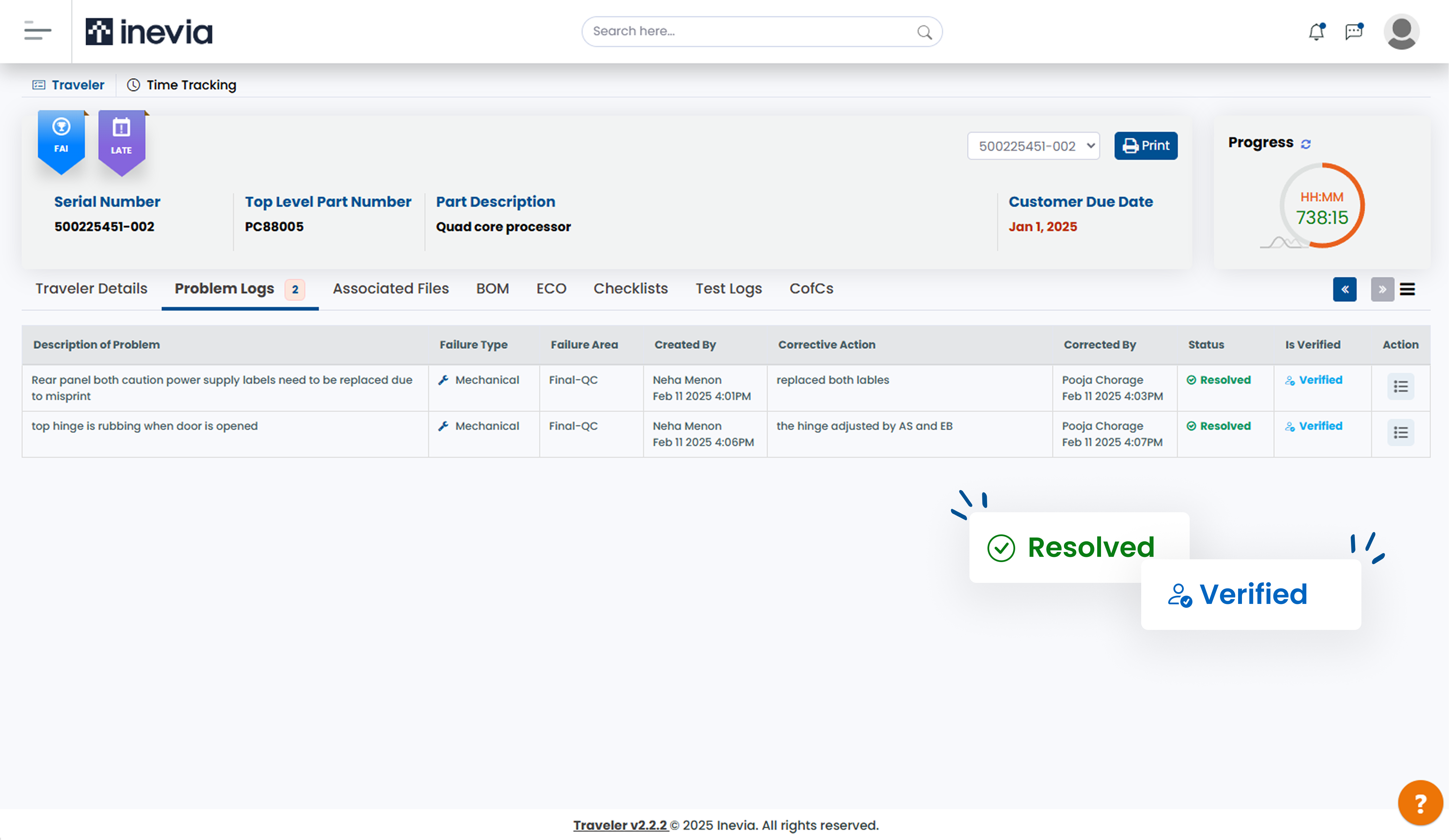

Stay proactive with tools to log issues, track defects, and flag special product requirements like compliance or FAI.

Know MoreTraceability & Genealogy

Track every product, ensure quality, and maintain precise product lineage with seamless visibility.

Know MoreTraveler MES transforms manufacturing by tackling complexities head-on, giving you the tools to do more with less hassle

Traveler Capabilities

Core functionalities that power solutions and drive results.

Bring it all together

Unite workflows, production data, and quality metrics into one easy-to-use platform for effortless oversight.

Your platform, your way

Tailor every aspect to match your unique needs, creating a personalized experience that works for you.

Flex with the flow

Adjust workflows on the fly to keep pace with the ever-changing demands of your manufacturing process.

Quality at the core

Track issues, defects, and compliance directly within the platform, ensuring a proactive approach to quality control.

Blogs

Frequently

Asked Questions

Curious about Traveler MES?

Check out the answers to some of the most commonly asked questions...

Traveler MES is a comprehensive manufacturing execution system designed to simplify and optimize your production process. By consolidating workflows, real-time data, and quality management in one platform, it helps you streamline operations, reduce inefficiencies, and increase overall productivity.

Absolutely! Traveler MES offers custom configurations, allowing you to tailor the system to match your unique production workflows, KPIs, and operational requirements, ensuring a seamless fit with your processes.

Traveler MES integrates quality assurance directly into the system, allowing you to track defects, monitor compliance, and proactively manage issues. This ensures superior product quality and compliance across your manufacturing process.

Inevia offers comprehensive support to ensure your Traveler MES implementation is smooth and successful. From onboarding to ongoing assistance, our team is dedicated to helping you maximize the value of the system at every stage.

Simplify Complexity in Manufacturing

Manufacturing doesn’t have to be complicated - our solutions make it smarter and faster.

Get in touch