Factories often appear efficient with machines running and teams on the floor. However, this efficiency is frequently supported by manual interventions, makeshift instructions, and constant human effort. The truth is, many factories are one missed step away from a costly delay. Operators often misunderstand instructions. Operators rely on memory. Standardized Work Orders vary from one shift to the next. And when problems do arise, it’s hard to pinpoint the source let alone fix it quickly.

This is especially true for small and mid-sized discrete manufacturers, where limited resources amplify the impact of every lost minute. Without standardized work orders for small manufacturers, teams often rely on memory, scattered notes, or outdated systems, resulting in confusion and costly downtime.

So, what’s the solution? It starts with having a system that creates, manages, and tracks standardized work orders. That’s exactly what Traveler MES is designed to do.

From Chaos to Clarity: The Need for Standardized Work Orders for Small Manufacturers

In many small and mid-sized manufacturing environments, many teams still manage their Standardized Work Orders through a mix of paper printouts, spreadsheets, and verbal communication. While this might seem like a manageable system, especially for smaller teams or simpler products, the reality is that it introduces invisible complexity into every production cycle.

Without a clear, Standardized Work Orders process in place, even your most experienced operators can struggle to stay aligned. Here’s what that looks like in practice:

- Paper-based SOPs quickly become outdated as product specs change, yet old copies often remain on the shop floor. Operators might follow yesterday’s instructions for today’s product, resulting in rework or scrap.

- Excel sheets shared across departments or shifts often go out of sync. One team updates a sheet, another doesn’t see it. Instructions may be overwritten, lost, or misinterpreted especially when multiple product variants are in play.

- Verbal instructions, while convenient, are inconsistent. A supervisor may explain a task one way in the morning and another way later in the day. New operators rely on hearsay, and tasks are completed based on what someone thinks is correct.

- Quality issues often go unlogged or reported too late. Without a structured, in-the-moment reporting process, problems surface only at the end of the line or worse, after the product has shipped.

- Production status is usually tracked manually. Managers rely on floor walks or calls to check on order progress. This delays decision-making and makes it hard to spot issues before they affect delivery.

What Inefficiencies Often Lead to:

These inefficiencies might not feel disruptive in isolation but over time, they compound into serious operational costs. Here’s what they often lead to:

- Frequent production delays due to missing materials, unclear instructions, or waiting for clarification.

- Rework and scrap, especially when products are assembled out of sequence or without the latest revisions.

- Teams often fail to log quality issues or report them too late

- Missed delivery timelines, affecting customer trust and potentially leading to penalties or lost contracts.

- Operator stress and burnout, especially when team members feel responsible for problems they couldn’t prevent due to process breakdowns.

- At first glance, these may seem like small, manageable setbacks. But added up over weeks and months, they represent a major drain on time, efficiency, and profit not to mention your team’s morale.

Traveler MES: A Game-Changer in Standardized Work Orders for Small Manufacturers

Traveler MES helps manufacturers eliminate ambiguity and bring structure to their operations. It transforms manual, inconsistent work order processes into Standardized Work Orders digital workflows ones that are repeatable, trackable, and reliable.

Here’s how it works:

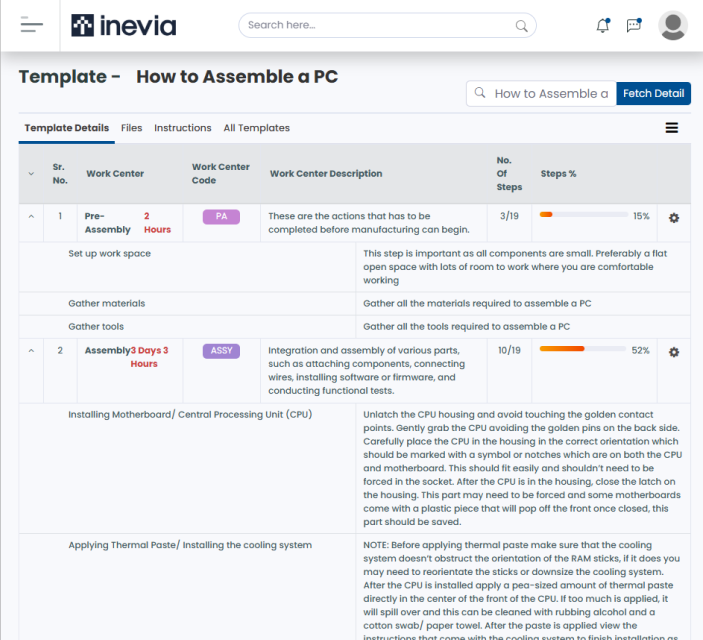

1. Create a Structured Work Order Template

Templates are the foundation of standardization. With Traveler MES, you can build custom work order templates that include:

- A unique product name and 8-digit code for every order

- Designated work centers and process sequences

- Time allocations for each step to support better scheduling

- Approval points for inspections and quality checks

Once created, these templates can be used across multiple products or modified for custom builds ensuring every team starts with the same roadmap.

2. Generate Traveler Documents That Guide Execution

Each order, once scheduled, automatically produces a Traveler Document. This digital record follows the product throughout the entire production cycle.

It includes:

- Clear, step-by-step instructions tailored to each workstation

- Operator log-ins and timestamps to track who did what and when

- Inline quality checkpoints with room for notes or photo attachments

- Fields for real-time issue logging so problems are documented as they occur

This eliminates the need for separate QA forms or scattered communications. Everyone works from the same set of instructions, no matter the shift or department.

3. Log Problems Without Stopping Production

Traveler MES allows operators to report issues directly within the Traveler Document. Whether it’s a defective component, missing material, or unclear instruction, it can be flagged in real time.

Benefits include:

- No need for follow-up meetings or delayed reports

- Supervisors receive immediate alerts for critical issues

- Problems are tied to specific serial numbers and process steps

- Quality concerns are addressed before they escalate

This proactive feedback loop prevents minor issues from turning into costly delays.

4. Trace Every Unit with Serial Number Tracking

Every discrete product has a lifecycle. Knowing that lifecycle is what allows you to resolve issues quickly, comply with audits, and maintain customer trust.

Traveler MES builds serial number tracking into the core of the production workflow also known as traceability and genealogy. With it, you can:

- Assign serial numbers at the part or assembly level

- Track every action tied to that unit

- Identify affected products during a quality event

- Trace defects to the exact process, station, or shift

This level of traceability supports better decision-making and streamlines compliance documentation.

5. Real-Time Production Tracking: Supporting Standardized Work Orders

The Real-Time Order (RTO) Dashboard gives supervisors and production managers full visibility into ongoing work. No more waiting for end-of-shift updates or walking the floor to get answers.

You can instantly see:

- Which orders are in progress, complete, or delayed

- Where bottlenecks are forming

- If departments are over capacity or underperforming

- How actual output compares to planned targets

This data helps teams stay ahead of disruptions, manage priorities more effectively, and continuously improve workflows.

Why Standardized Work Orders Matters for Small and Mid-Sized Manufacturers

If you run a small or mid-sized operation, you’re likely facing several challenges that can complicate production. Here’s why it matters:

- Your team wears multiple hats: Everyone in your workforce is juggling various roles, from production to quality control, which can lead to mistakes and inefficiencies.

- You don’t have a full-time IT department: Without dedicated IT support, addressing technical issues can be time-consuming and disrupt your production flow.

- Your production environment is complex but resource-limited: You’re working with custom-built products, specialized parts, and varying Standardized Work Orders, making standardization even more crucial but harder to achieve.

- You need simple solutions that deliver consistent results: With limited resources, it’s essential to find solutions that are straightforward and effective, reducing complexity while ensuring reliable outcomes.

Traveler MES was specifically designed with these challenges in mind. It simplifies daily operations by:

- Reducing dependency on memory or paperwork: It ensures that everyone is on the same page with clear, standardized work orders.

- Helping your team focus on what matters most: With fewer distractions and a more organized workflow, your team can focus on getting the job done right

Traveler MES provides the support you need to streamline operations and improve efficiency, all while working within the constraints of a small or mid-sized manufacturing environment.

On Time Delivery Starts with Standardized Work Orders

With a standardized work order system in place, you unlock measurable improvements:

- Operators know exactly what to do and when

- Mistakes due to unclear instructions are drastically reduced

- Teams report and resolve issues without delay

- Production schedules are met with confidence

- Customers receive consistent, high-quality products

Most importantly, you move from a reactive workflow to a proactive system that is built to grow with your business.

Ready to Reduce Downtime? Standardize Work Orders Today

If your current process feels scattered, inconsistent, or overly dependent on spreadsheets and paperwork, Traveler MES can help. It’s time to leave behind the firefighting and run a factory that flows.

Book a demo today and discover how standardized work orders can simplify your operations, reduce delays, and improve traceability without overhauling everything you’ve built.