Production delays don’t start on the factory floor. They begin long before the first product takes shape. Delayed approvals, unclear task ownership, missing materials, these issues tend to show up during the planning stage. And by the time the MES system goes live, it’s often too late to fix them without losing days or even weeks.

For discrete manufacturers, preventing these early-stage breakdowns is critical. This is where Flight Deck fits in. It is a structured project management platform built specifically for the pre-production phase, right before the MES (such as Traveler MES) begins. It gives your team the visibility, structure, and accountability needed to make sure production starts on time.

What Causes Delays Before the First Product is Made?

In theory, manufacturing should follow a straight path. But in practice, projects get delayed for reasons that have nothing to do with machines or shop floor efficiency. Delays start with:

- Incomplete or inaccurate BOMs

- Drawings that have not been approved

- Disconnected communication between engineering, procurement, and QA

- Tasks without owners or timelines

- Manual planning using spreadsheets and emails

Many teams do not realize that these issues are rooted in pre-production. Once MES begins, there’s little room to catch up. That’s why manufacturers need a way to get control of the early phase. A pre-production workflow tool like Flight Deck helps resolve these issues at the source.

Flight Deck: Bringing Structure to Pre-Production Chaos

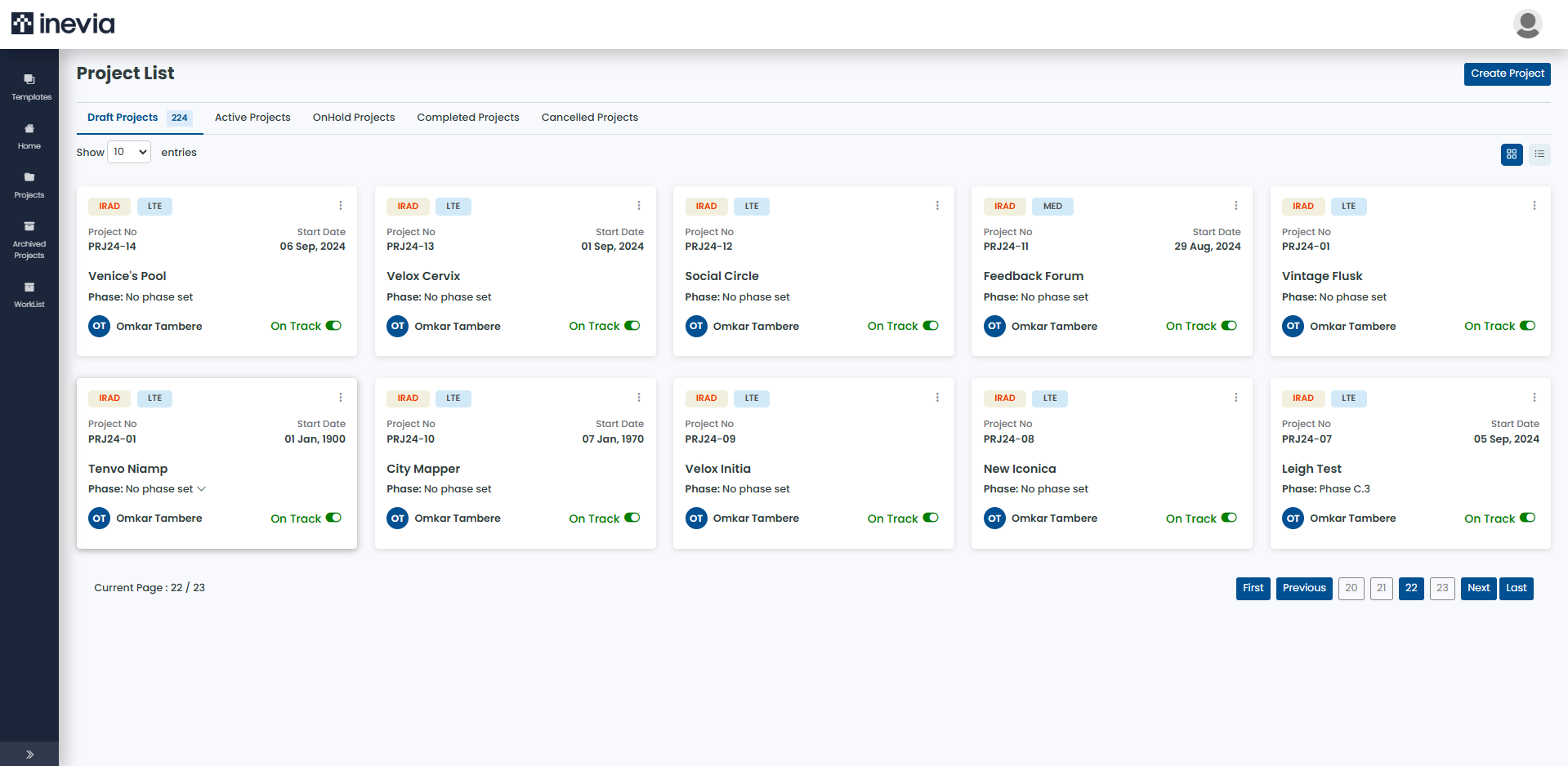

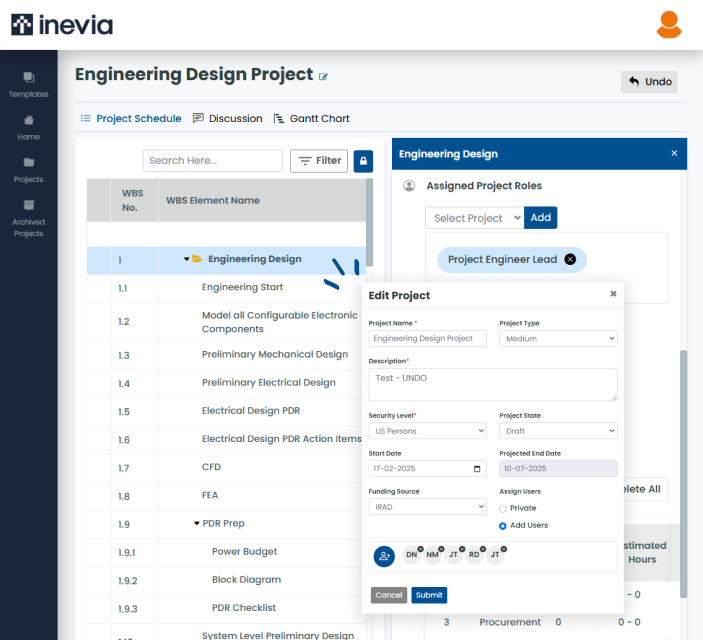

Flight Deck was designed for manufacturers who want better control of everything that happens before production begins. It gives your team a central place to assign tasks, track progress, manage approvals, and stay aligned across functions.

It contains five core components that turn your pre-production workflow into a clear, repeatable process.

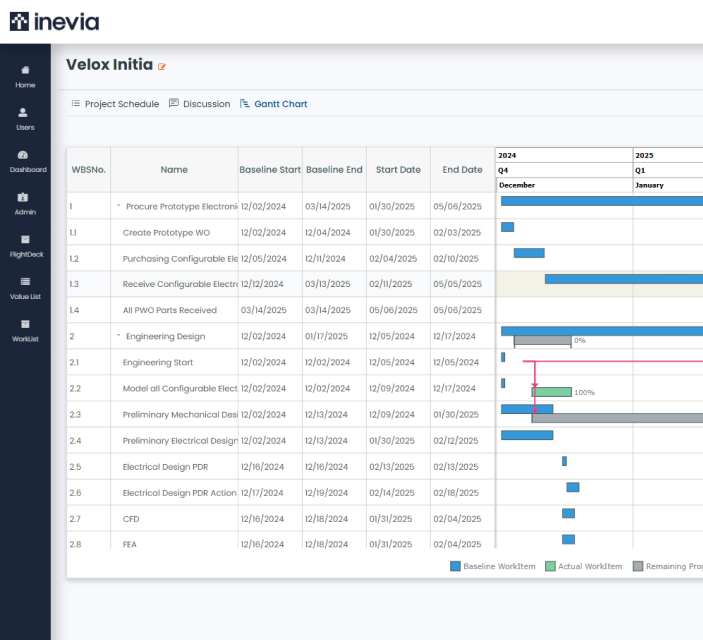

1. Templates and Work Breakdown Structure (WBS)

Flight Deck starts with ready-to-use templates, customized for your factory’s processes. These templates are structured into a Work Breakdown Structure (WBS). Every task is broken into phases and sub-tasks using a format such as 2.17.2. Each task is tied to an owner, a deadline, and a clear progress status.

Each phase in WBS goes through four stages, making sure the team doesn’t miss critical steps. Instead of hoping someone handles a task, you can see exactly what’s done, what’s in progress, and what’s at risk.

This structure allows you to eliminate confusion about what comes next. Teams can prepare, review, and execute without delays.

2. Product List Customization Based on Teams and Regions

In global manufacturing, not every team can or should access the same tasks. Flight Deck allows you to customize your product list and workflows based on region, compliance, and user profile.

For instance, users outside the US may have full access to certain views, while US-based teams or citizens may have restricted access. For projects funded through IRAD or CPO, Flight Deck ensures that workflows stay compliant with funding-specific requirements.

This customization saves time and prevents compliance mistakes during critical stages of planning.

3. Archived Projects for Future Use

Each completed project in Flight Deck is automatically archived. This gives your team access to past workflows that can be reused or adapted for future launches.

You can review what worked, avoid repeating past mistakes, and build consistent execution across programs. For complex manufacturing environments, this historical tracking becomes an asset for quality, repeatability, and speed.

4. Time Tracking for Tasks and Phases

Time tracking in Flight Deck helps you understand how long each task or phase actually takes. Your team logs hours against specific tasks, which allows operations leaders to analyze where time is being spent.

This data is useful for building more accurate schedules, identifying bottlenecks, and planning future projects with better estimates. Over time, your factory becomes more predictable, and your planning improves.

5. Team Ownership and Coordination

Cross-functional communication is often where production plans start to fall apart. In Flight Deck, every task is assigned to a user, and the full team has visibility into who is doing what.

This removes ambiguity from the process. Teams don’t need to chase updates. Everything from task status to ownership is tracked in one system. If an approval is delayed or a step is skipped, it becomes immediately visible.

With everyone on the same page, the factory can avoid unnecessary rework, missed deadlines, or finger-pointing during the final hours of planning.

Real Manufacturing Scenarios Solved by Flight Deck

Let’s explore a few examples where Flight Deck helps avoid production delays:

1. Delayed Material Readiness

In many factories, the procurement team only discovers missing materials once the schedule has already begun. Flight Deck flags these issues early, linking BOM completion and vendor readiness to the project timeline. The procurement team knows what to expect and when to act, reducing the risk of last-minute delays.

2. Engineering Approval Not Finalized

Engineering changes or pending drawing approvals often lead to stalled production. Flight Deck includes approval workflows that stop tasks from progressing until all sign-offs are complete. This keeps the timeline protected and ensures nothing gets overlooked.

3. Team Miscommunication

With multiple departments involved, handoffs are easy to miss. Flight Deck prevents this by offering shared visibility across the full team. Everyone knows what has been completed, what is due next, and where the project might be falling behind. This improves coordination and reduces stress before the MES kicks in.

Ready to Start Your Factory On Time? Use Flight Deck

If your production planning still depends on scattered spreadsheets, disconnected tools, or manual follow-ups, the risk of delay is always present. Flight Deck gives you a clear, proven structure for managing the most unpredictable part of the production cycle – the planning phase.

You can:

- Improve factory planning before MES

- Streamline production setup

- Use a purpose-built pre-production workflow tool

- Gain control over manufacturing delay management

- Avoid production delays that cost time, money, and trust

Start smarter. Start on time. Let Flight Deck show you what your factory is capable of when everything is planned right the first time.