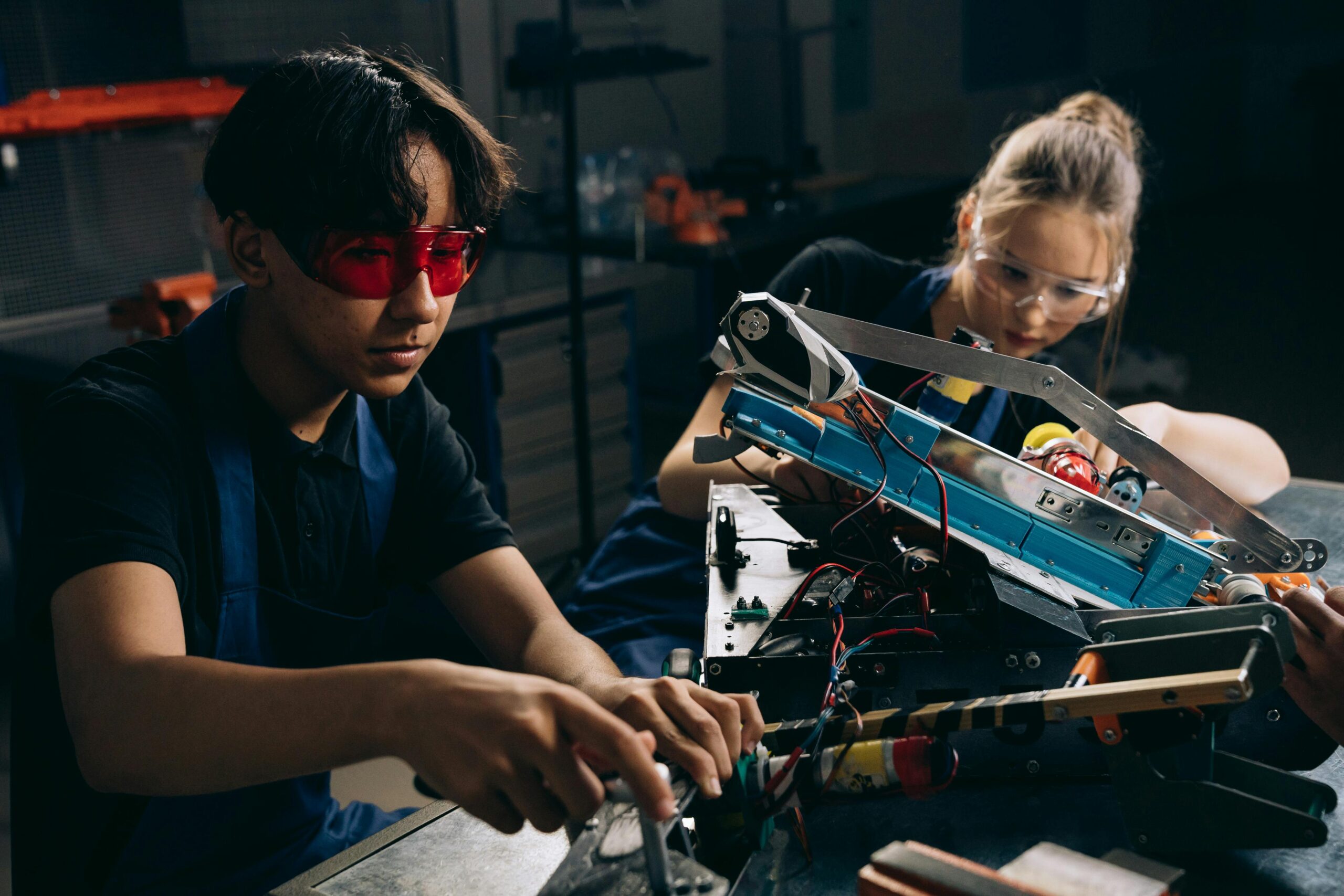

For discrete manufacturers, operational efficiency and precision are non-negotiable. From automating workflows to offering real-time insights, MES is the game changer transforming traditional system of discrete manufacturing and giving it a modern twist. By automating workflows, integrating data, and delivering actionable insights, MES empowers manufacturers to bridge the gap between planning and execution, driving efficiency and competitiveness.

What Is Manufacturing Execution System (MES)?

A manufacturing execution system (MES) is a software that enhances manufacturing operations by improving efficiency, quality, and visibility. It integrates real-time data to give manufacturers a clear and unified view of their production floor. In discrete manufacturing, where products are uniquely assembled, MES ensures that every component is traceable and that every process aligns with operational goals.

MES can help discrete manufacturers address high-priority pain-points such as production tracking or quality control, leading to high-quality finished goods.

Why Discrete Manufacturers Need MES?

Live Visibility Into Operations

MES offers real-time insights into your manufacturing processes. It allows you to track job progress, monitor production flow, and identify bottlenecks before they affect the operations. Inevia’s Traveler MES allows you to experience all these features, helping SME manufacturers gain live operational visibility for every stage, making sure that there are no problems or surprises on the production floor.

Unified Dashboard

As a manufacturer, it is difficult to have a unified overview of the entire process, however MES can provide that by integrating into existing ERP systems and connecting with different departments to ensure centralisation of processes. This helps to have better team collaboration, avoid unnecessary delays, and reduce the fear of missing deadlines.

Enhanced Quality Assurance

In the world of discrete manufacturing, quality sets the standard for business growth. MES embeds quality checks through the production process to ensure that every product meets industry standards. By integrating quality management tools such as Traveler MES, you can minimize defects and ensure consistent output, saving time and resources. Quality metrics can be set in MES to trigger automated quality inspections when variances occur unexpectedly.

Understanding The Benefits Of MES

MES offers numerous benefits that enhance operational efficiency, improve decision-making, and ensure quality control throughout the manufacturing process. Here’s how these features translate into practical advantages for operations:

Production Efficiency:

MES streamlines workflows and reduces downtime by identifying inefficiencies early. By automating manual processes, manufacturers can increase output without compromising quality.

Data-driven Insights:

MES collects and analyses real-time data, providing manufacturers with actionable insights that improve production planning, resource allocation, and workflow optimization. This ensures that operations stay agile and responsive to changing demands.

Component Traceability:

In discrete manufacturing, traceability can be a big challenge to overcome. MES ensures that every component of the goods can be traced back to their original source to aid quality assurance, making it easier to meet industry regulations and customer requirements.

Elevate Your Operations With MES

Discrete manufacturing demands precision and efficiency. A robust MES solution provides live visibility, seamless workflows, and actionable insights to optimize your processes. Take the next step by implementing Inevia’s Traveler MES today to enhance operational efficiency, streamline workflows, and drive your manufacturing operations forward.