In small and mid-sized factories, time isn’t just money; it’s reputation, customer satisfaction, and operational momentum. One small delay can trigger a domino effect, stalling production lines, missing deadlines, and stretching costs beyond control.

For discrete manufacturers who rely on precision, traceability, and timely delivery, these delays can be costly in more ways than one. But what if downtime wasn’t just monitored after the fact, but prevented altogether?

Traveler MES by Inevia is built specifically to tackle these challenges from the ground up. Not only does it align with your production workflow and it actively improves it, helping you reduce downtime at every critical point in your cycle.

Why Downtime is More Than Just Lost Time

In discrete manufacturing, every part is unique, every batch has a story, and every process must follow a strict sequence. When production stops, you don’t just lose minutes you lose trust.

Downtime can come from:

- Miscommunication between teams

- Missing or incomplete instructions

- Poor visibility into where a product is in its cycle

- Unlogged quality issues

- Delays in raw material prep or inspection

These aren’t just technical hiccups, they’re blockers to operational efficiency. They slow your team, stress your delivery timelines, and weaken your competitive edge.

The Hidden Costs of Production Delays

You might not always see the numbers, but they’re there.

- Idle time: Machines wait, people wait, orders wait.

- Confusion and rework: Operators miss steps due to outdated instructions.

- Delayed shipments: One late order means a missed customer window.

- Wasted materials: Without clear tracking, you might scrap parts that could’ve been fixed.

For small and mid-sized businesses where resources are tight, these losses hit harder. Traveler MES helps you cut through the noise and focus on what matters smooth, traceable production with minimal downtime.

How Traveler MES Works Across Your Manufacturing Cycle

Let’s walk through how Traveler MES supports each step of your discrete manufacturing workflow while actively reducing downtime throughout the process.

1. Knitting: Organizing the Production Plan

Every manufacturing process begins with a clear plan and that’s exactly what the knitting stage is all about. This is where you define the part, create a work order, and get your team aligned before production even begins. With Traveler MES, this stage becomes incredibly efficient. You can set up each job using a standardized template that includes the part’s identity defined by an 8-digit code, security level, and the appropriate work centers assigned for production. Everything is structured and centralized, reducing the back-and-forth and confusion that usually eats into valuable production time.

How it helps reduce downtime: Instead of teams losing time trying to figure out next steps or searching for missing instructions, everything they need is already documented and ready to go from the beginning. It sets the tone for a smooth, uninterrupted production cycle.

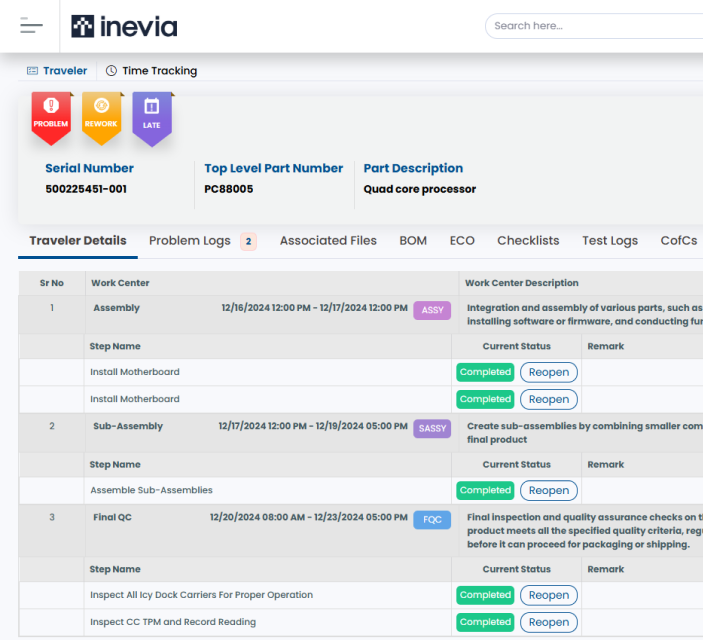

2. Product Genealogy: Serial Number Tracking and Traceability

Every unit you produce carries a story. From raw material to finished product and traveler MES makes sure you never lose track of your story, With serial number tracking built right into the system, you get a complete view of each product’s journey. You can trace where it’s been, who worked on it and what exactly was done at each step in the product genealogy phase.

How it helps to reduce downtime:

Let’s say a defect pops up later during QA or after delivery. Instead of pausing production to dig through paperwork or guess where things went wrong, you already have the full trail. That means less disruption and faster resolution.

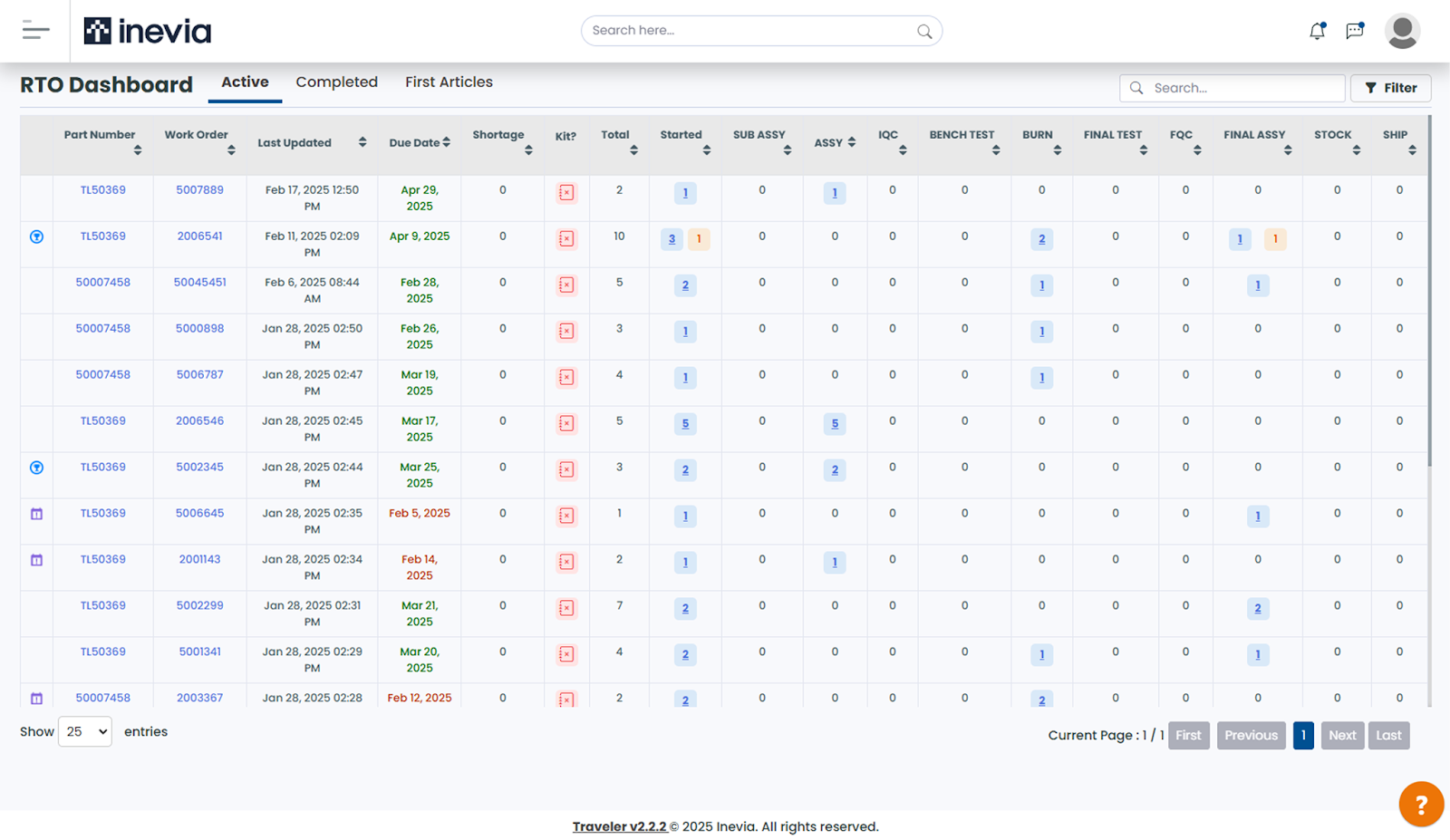

3. Production Tracking: Live Status with Real-Time Order (RTO) Dashboards

As each product makes its way through your shop floor, Traveler MES keeps you in the loop with real-time production tracking. The RTO dashboards show live updates on where every order stands whether it’s moving ahead smoothly or stuck at a work center.

How it helps reduce downtime:

You don’t need to send someone to chase down status updates. If there’s a bottleneck or delay, you see it right away and so you can fix it before it escalates. It keeps the production line flowing without unnecessary interruptions.

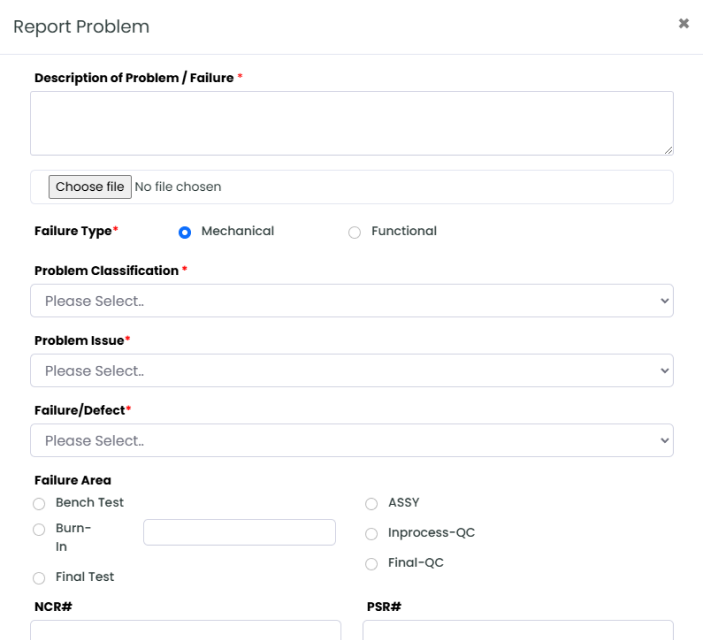

4. Quality Inspection: Built-In Reporting for Immediate Action

When a defect is found, timing is everything. Traveler MES enables your operators to report issues on the spot right inside the traveler document. There’s no need to stop the line or wait to fill out paper forms. Quality checks become part of the flow, not a separate task.

How it helps reduce downtime: Since problems are logged instantly, your team can act faster and avoid the snowball effect of unresolved issues. There’s no backlog of QA reports to deal with later.

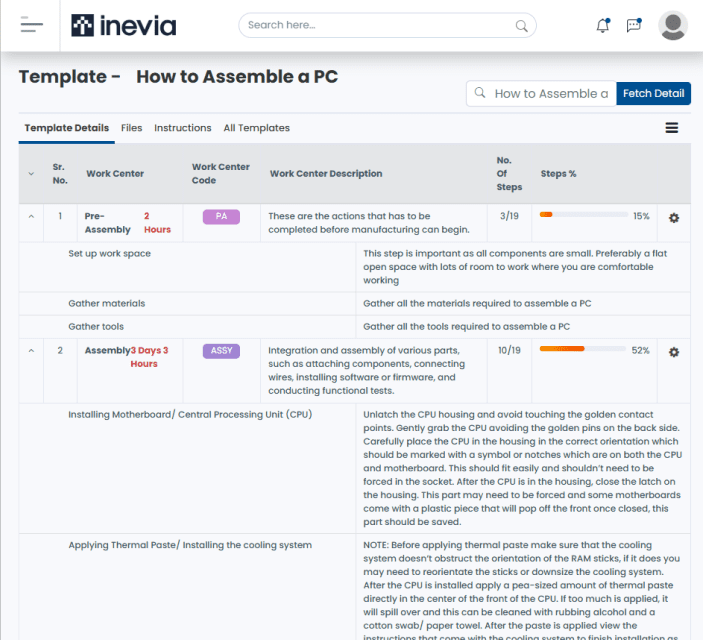

5. Digital Work Instructions: Clarity at Every Step

Printed SOPs often become outdated or get misplaced, slowing down your operators and causing unnecessary errors. Traveler MES solves that with dynamic, digital work instructions. These are easy to follow, always current, and tailored to each specific task.

How it helps reduce downtime:

There’s no more confusion or delay while waiting for clarifications. Operators get accurate, step-by-step guidance directly on their screens, so they can do the job right the first time.

6. Dashboards: Centralized Oversight for Smarter Decisions

Traveler MES doesn’t just help on the floor it empowers your leadership too. Everyone from supervisors to department heads can access dashboards customized to their role. These dashboards give a clear view of productivity, user activity, issue logs, and more.

How it helps reduce downtime:

With no blind spots, your team leads can act on real-time data rather than assumptions. They see where support is needed and can make informed decisions faster keeping production on track.

Why Traveler MES Stands Out

Unlike many traditional MES systems that feel overloaded with features you’ll never use, Traveler MES is different. It’s lean, focused, and built from real, on-the-ground manufacturing experience and not just a software wishlist. Developed in-house by a team that understands the daily challenges of discrete manufacturing, it’s designed to solve problems not create new ones.

With Traveler MES, you’re not just capturing data. You’re taking charge of your production process. Here’s what you get:

- Full traceability of every part and every process, so nothing slips through the cracks

- Clear, standardized workflows that guide your team step by step

- Dashboards that reveal bottlenecks before they slow things down

- Live production tracking that gives you confidence in your next move

See It in Action

Traveler MES is already improving production for manufacturers just like you. If you’re facing recurring delays, unclear instructions, or scattered tracking systems, this is your chance to try something that fits the way you work. Book a demo today and discover how a smarter system can lead to smoother production, fewer delays, and better outcomes for your business.

Most manufacturers are set up and running within a few days. Our team ensures your system is tailored to your workflow.

FAQs

- Will it disrupt my existing processes?

Not at all. Traveler MES enhances your current process and it doesn’t replace it. It integrates seamlessly into what you already do.

- Do we need any special hardware or ERP system?

No. Traveler MES works independently and is cloud-ready, simple to access from your existing shop-floor systems.

- What kind of support do we get?

Our product team is hands-on, responsive, and ready to support your floor teams, not just your IT department.